Microlucent® Machining

The Next Wave of Machining & Drilling Solutions

ISO 9001 Certified

AS9100 Certified

IATF 16949 Compliant

ITAR Registered

YOU SHOULDN’T HAVE TO CHOOSE BETWEEN PRECISION, QUALITY, OR AFFORDABILITY

We believe your design deserves a better machining solution.

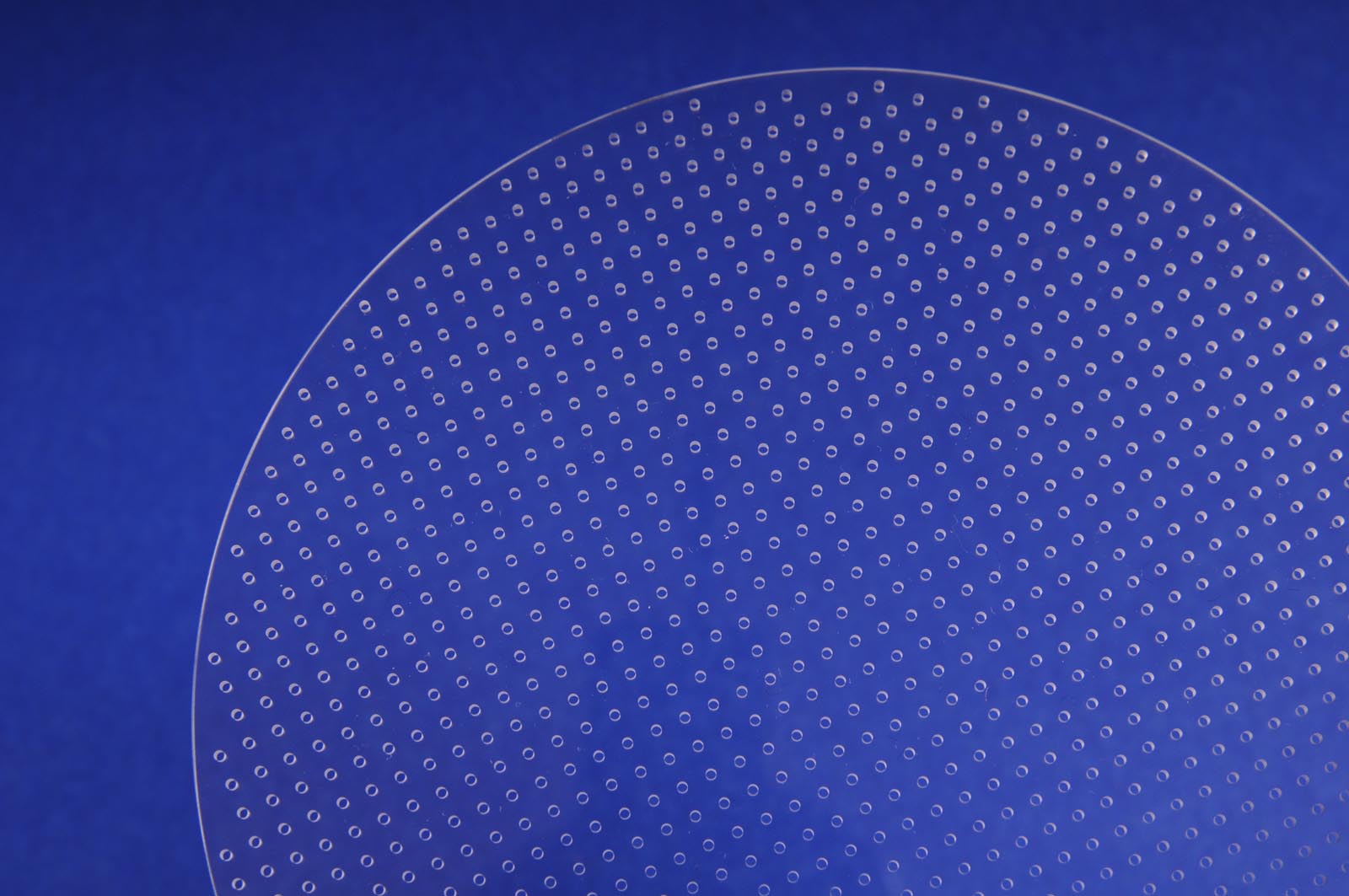

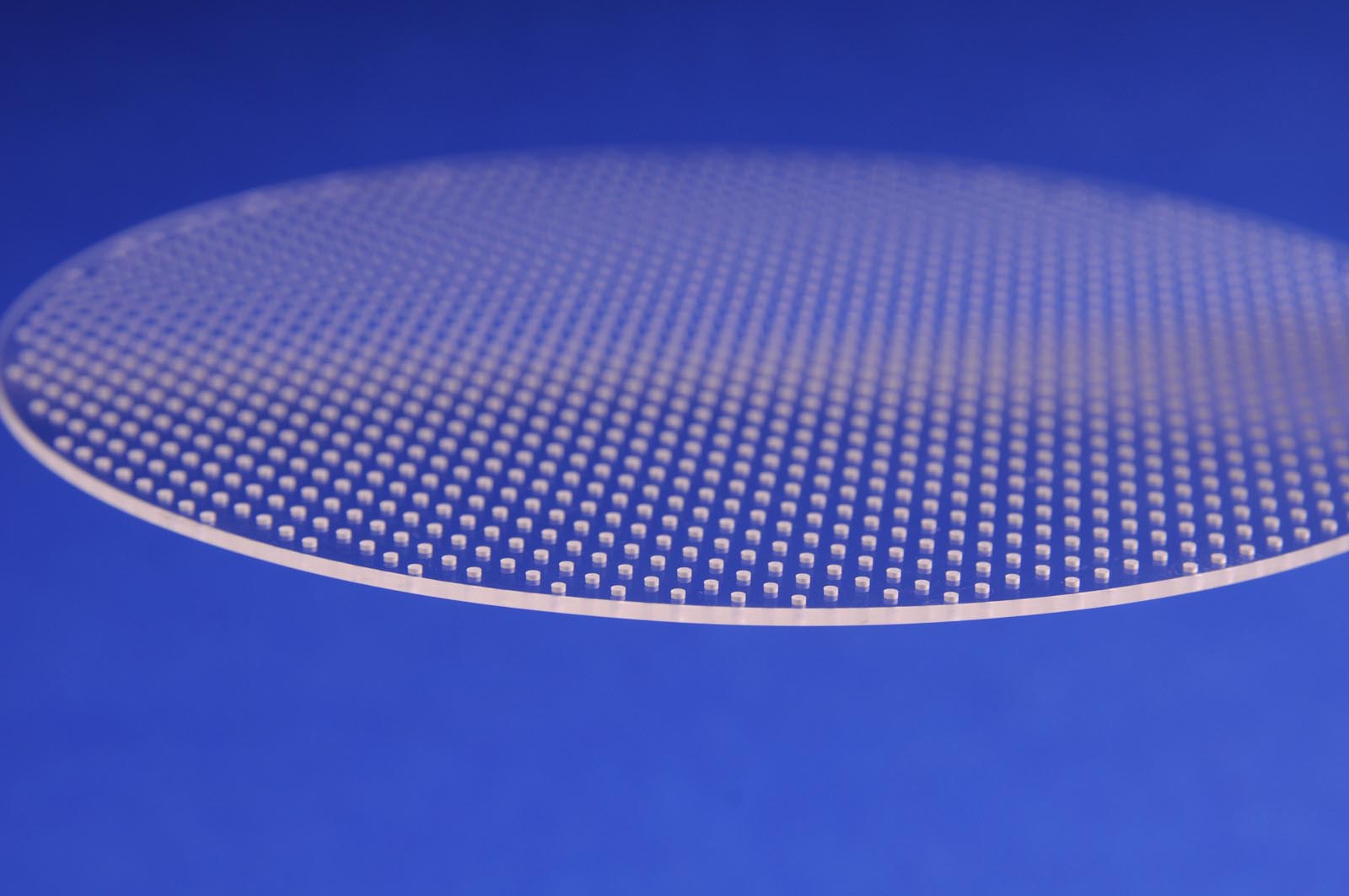

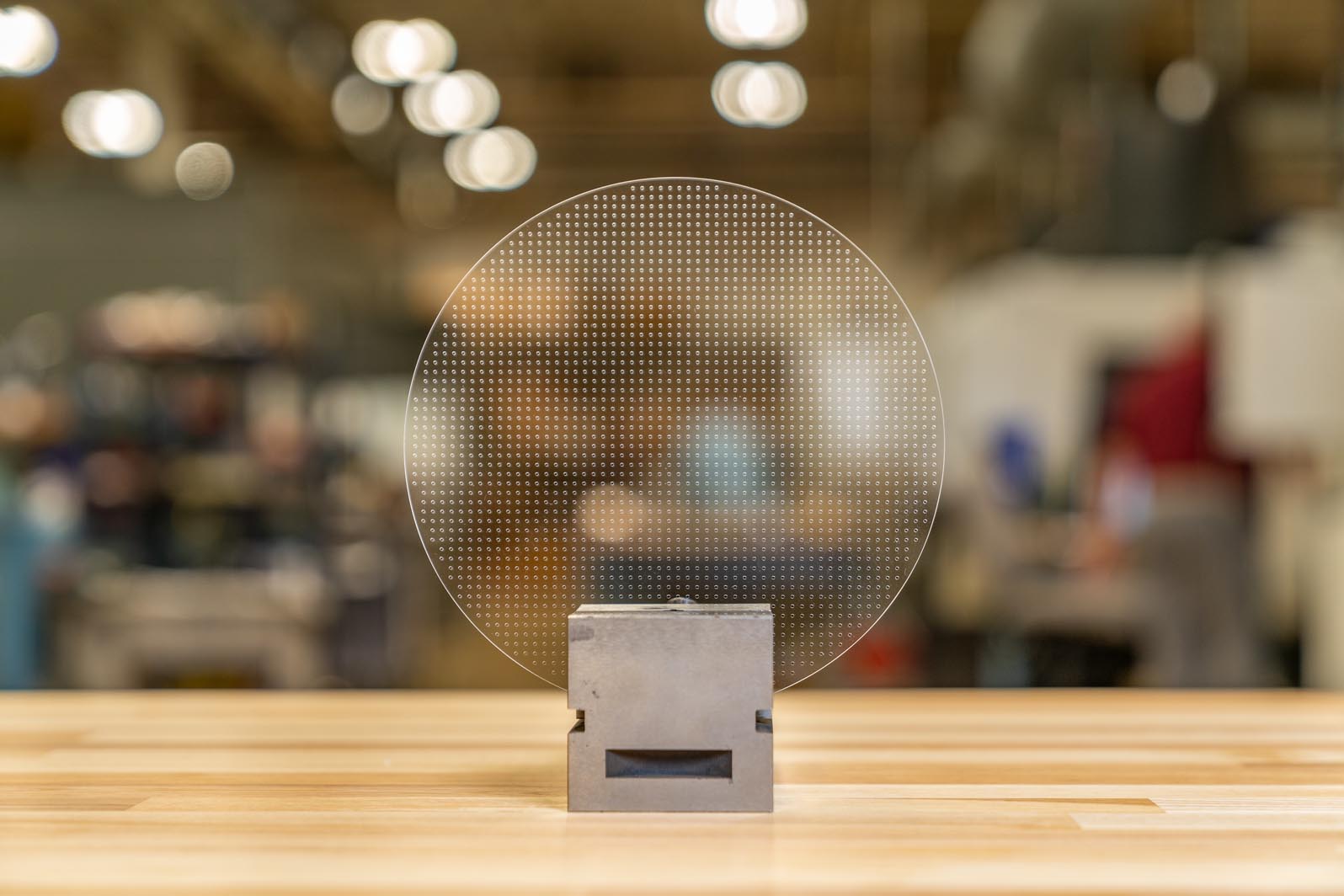

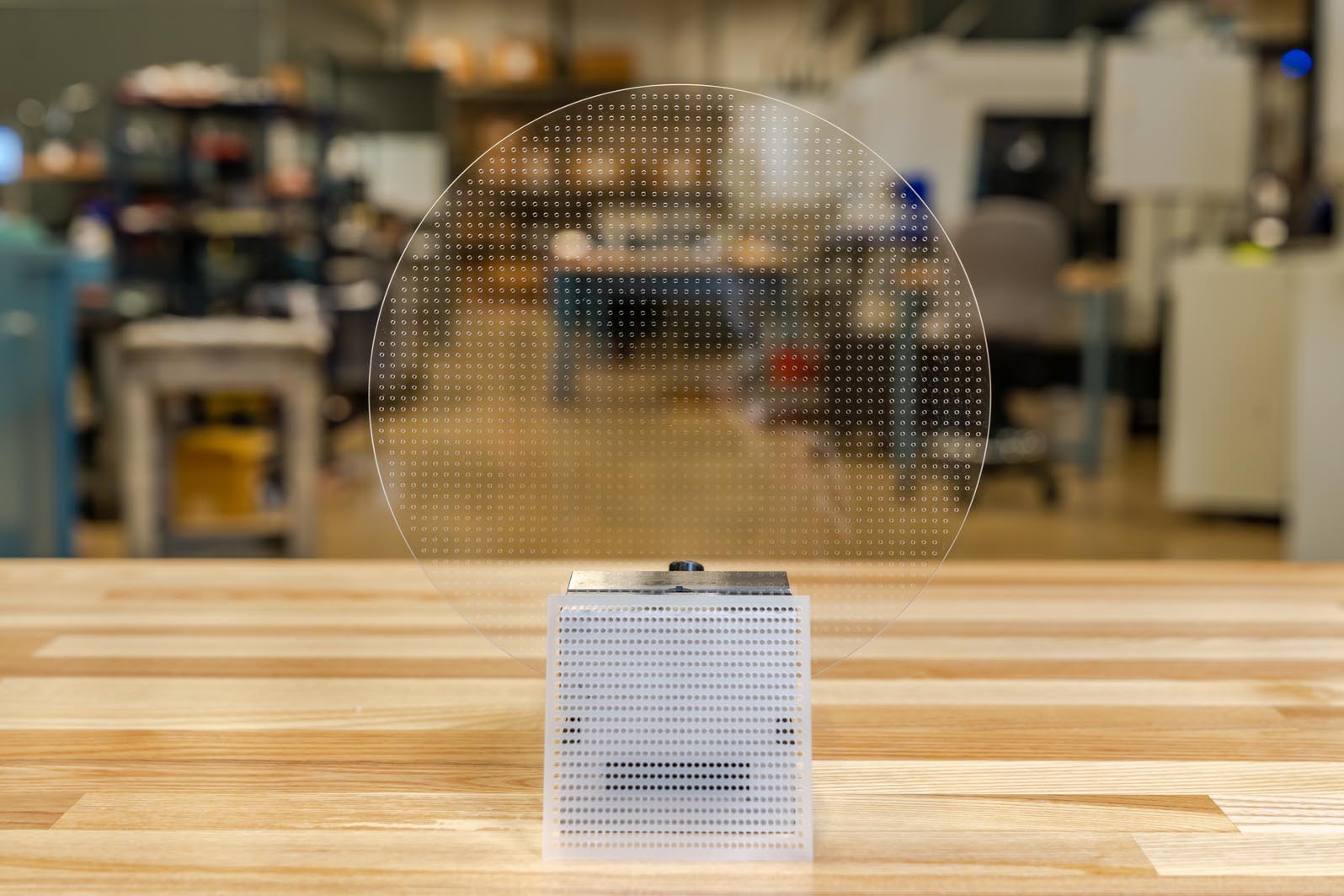

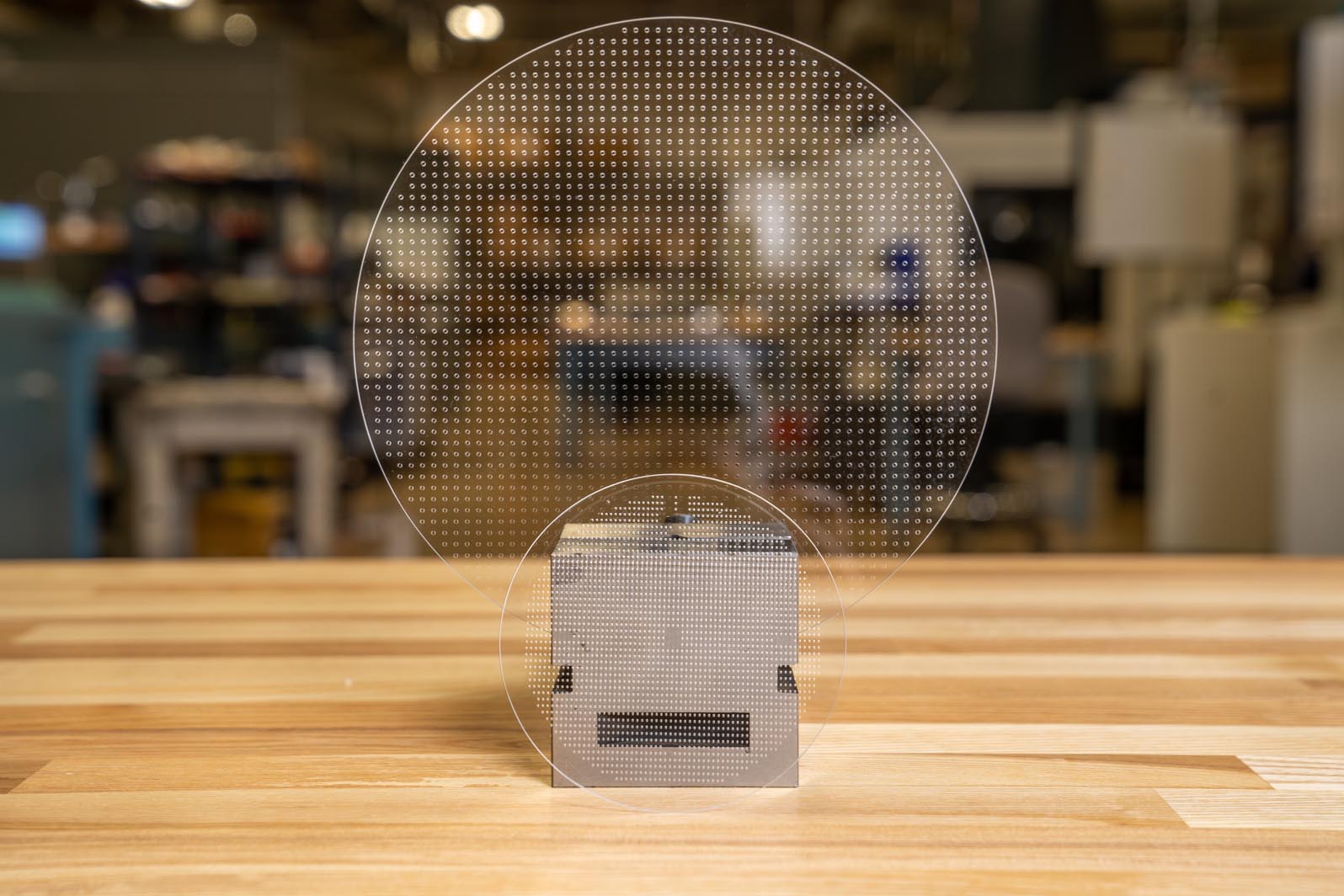

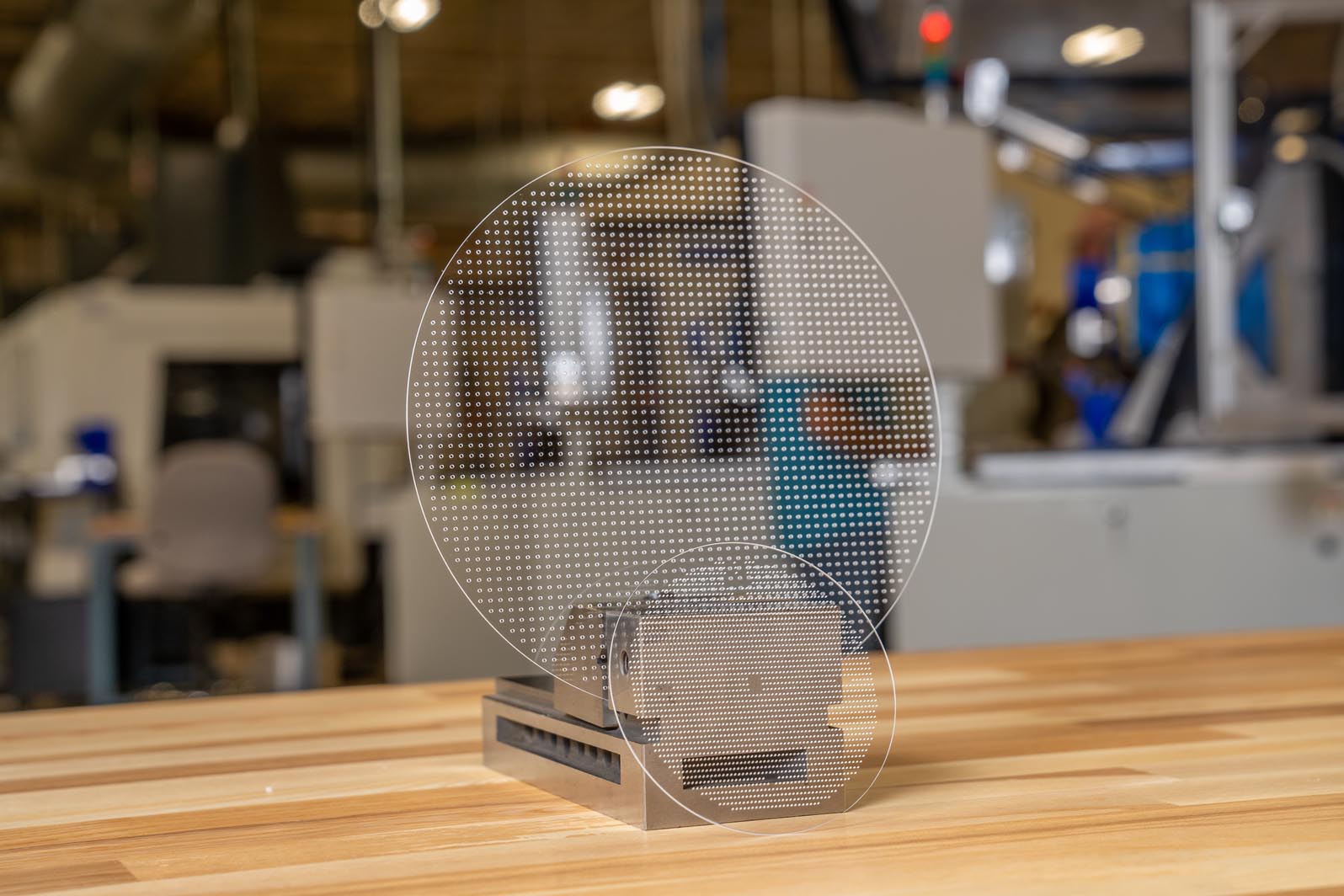

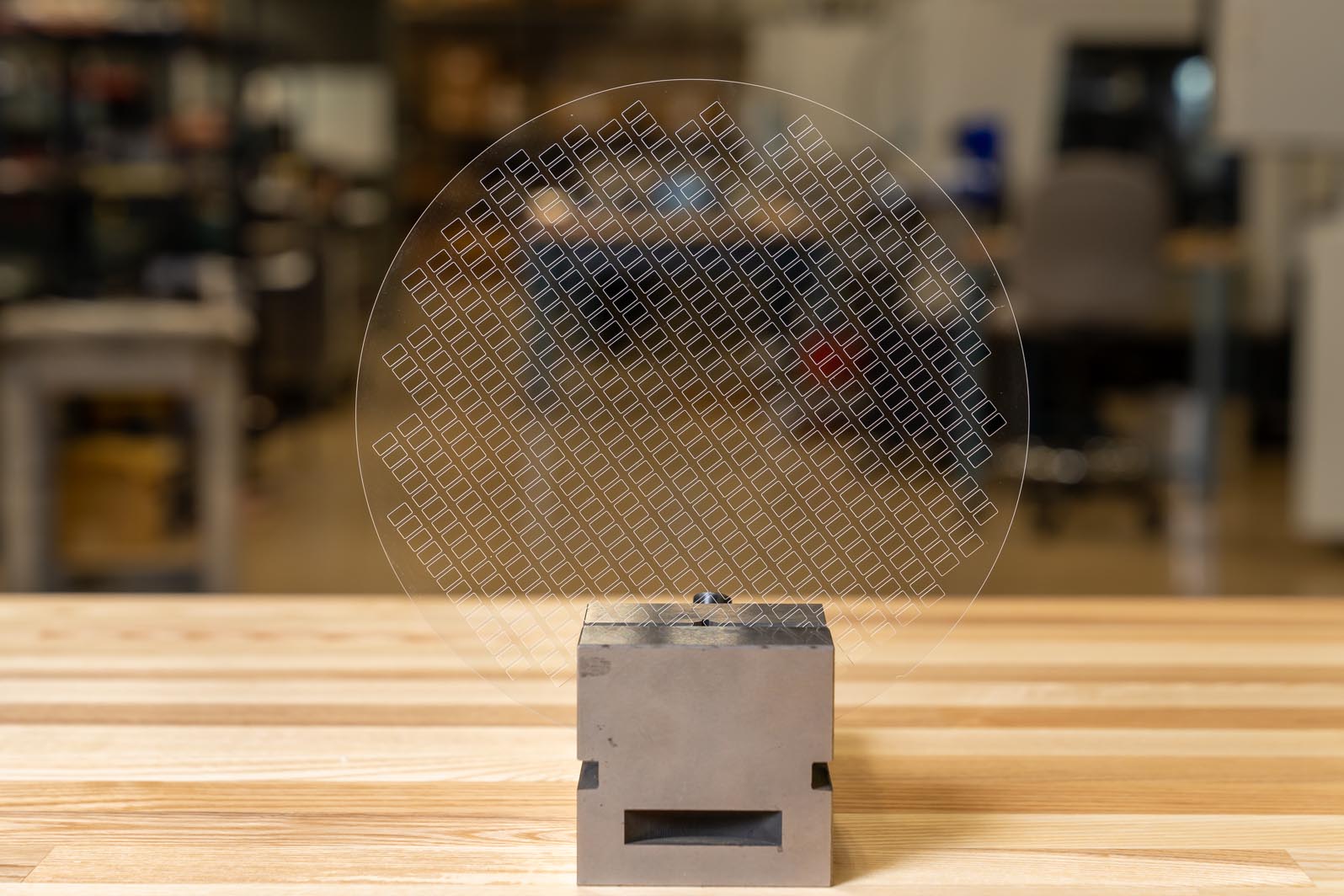

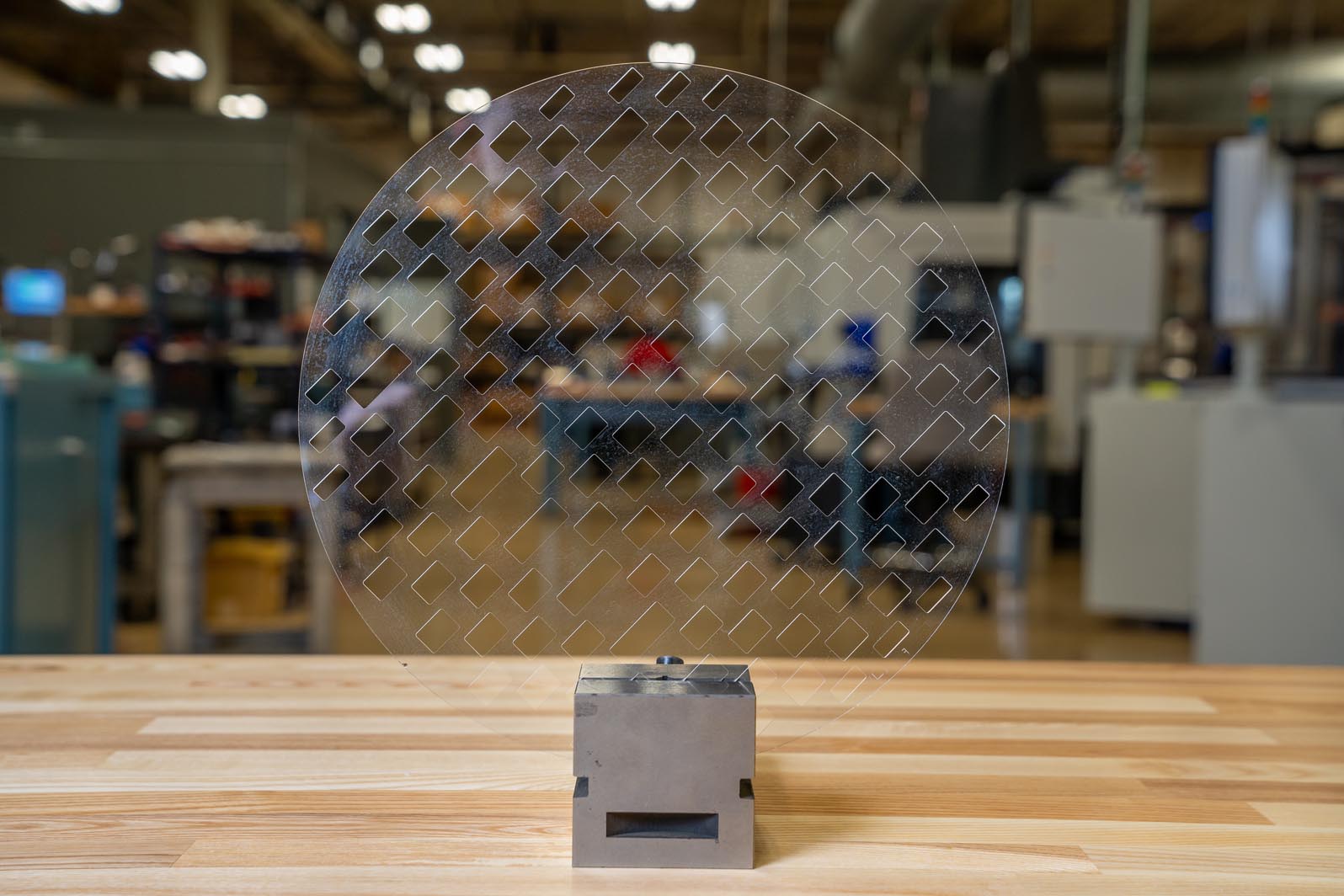

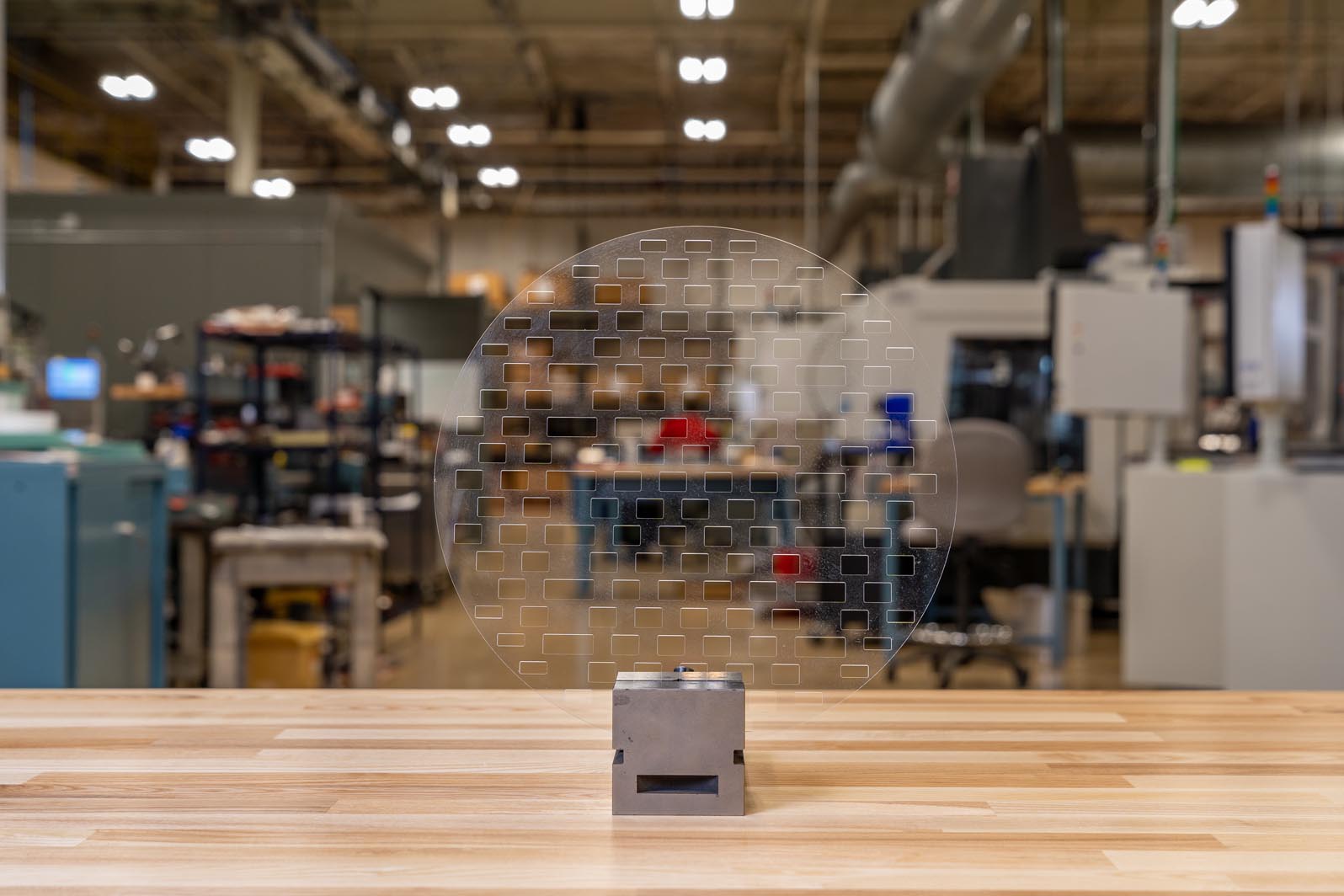

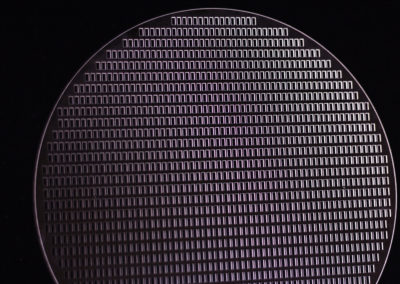

We use proprietary laser drilling technology to cut precise features in transparent materials so your team can execute its vision.

Materials We Machine ↓

MicroLucent® Machining can be used in transparent materials, including:

- Glass

- Sapphire

- Quartz

Features and Patterns Possible ↓

Bullen can machine a limitless number of different cuts and shapes, including:

- Round Holes

- Rectangular Holes

- Odd-shaped holes

- Slots

- Blind Cuts

- Cavities

- OD and ID Work

- Blind Cavities

Applications for MicroLucent® Machining ↓

Applications for MicroLucent Machining include:

- MEMS Glass Devices

- Quartz Semiconductor Gas Distribution Plates (GDP)

- Microfluidics Devices

- Through Glass Vias (TGV)

- Glass Interposers

Advantages of MicroLucent® Machining ↓

Bullen’s MicroLucent Machining process has many advantages over traditional machining.

- Micron level tolerancing

- Superior yields

- No damage to substrates

- No HAZ

- High throughput

GET IT ALL

MicroLucent® Machining offers high-precision quality at an affordable cost.

GLASS THICKNESS: UP TO 15MM

MINIMUM MICROHOLE DIAMETER: 40 µm

FEATURE ACCURACY: +- 10 µm

POSITIONAL ACCURACY: +- 15 µm

MIMIMUM PITCH 10 µm

TAPER ANGLE: NONE

CHIPPING: NONE

MICRO-CRACKS: NONE

A Simple Process to Solve Your Complex Engineering Need

1

Talk to Our Team

2

plan

3

Prototype & pilot

4

produce

News

Bullen Ultrasonics specializes in the precision machining of advanced ceramic components. We serve global companies in the Aerospace, Automotive, Life Sciences, Medical, MEMs, Telecommunications, and Semiconductor industries. Due to the variety of parts, machining challenges, and materials we work with, we have developed custom, precision machines to exceed customer expectations. Many customers turn to us […]