Microlucent® Machining

The Next Wave of Machining & Drilling Solutions

ISO 9001 Certified

AS9100 Certified

IATF 16949 Compliant

ITAR Registered

YOU SHOULDN’T HAVE TO CHOOSE BETWEEN PRECISION, QUALITY, OR AFFORDABILITY

We believe your design deserves a better machining solution.

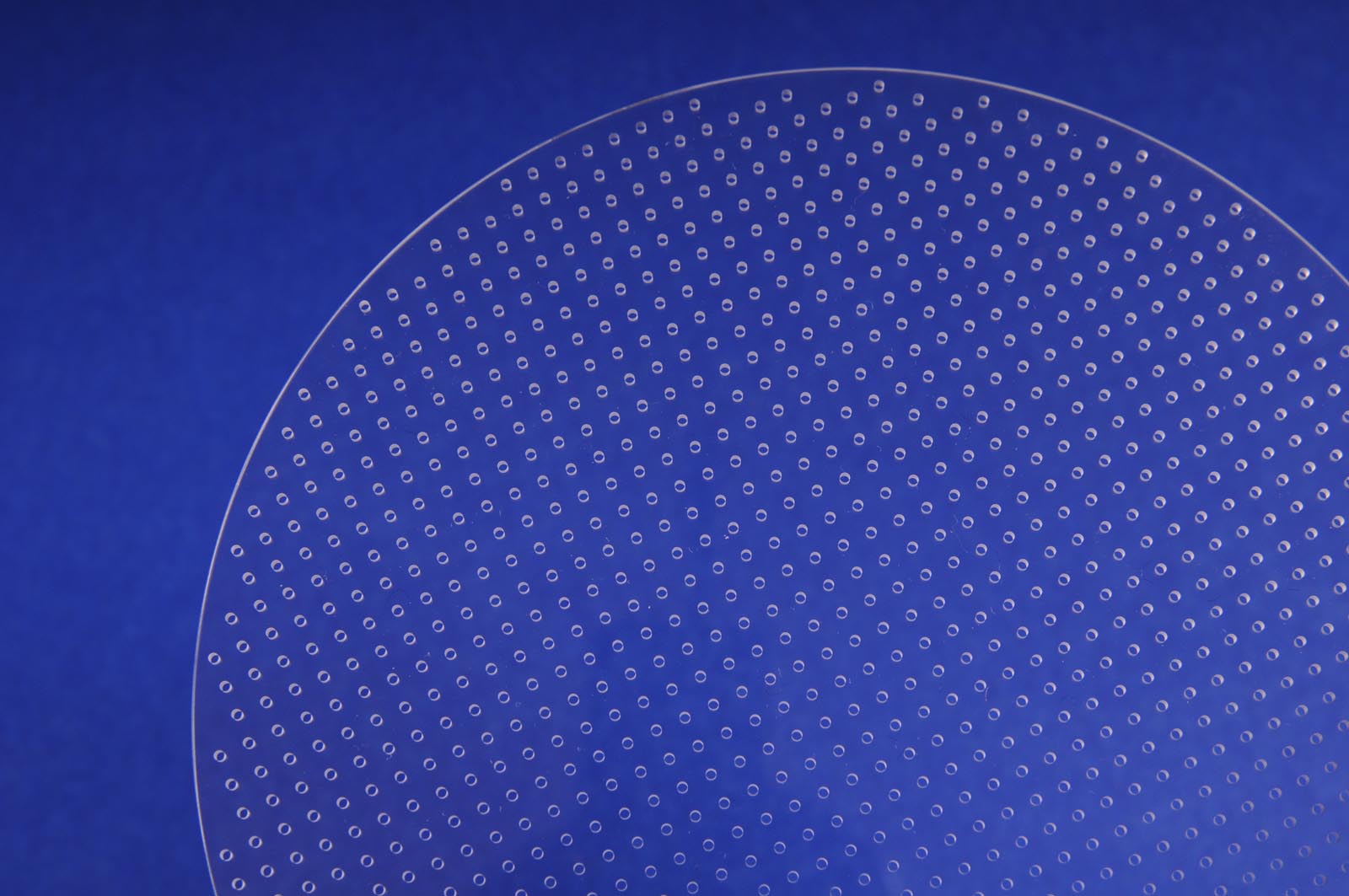

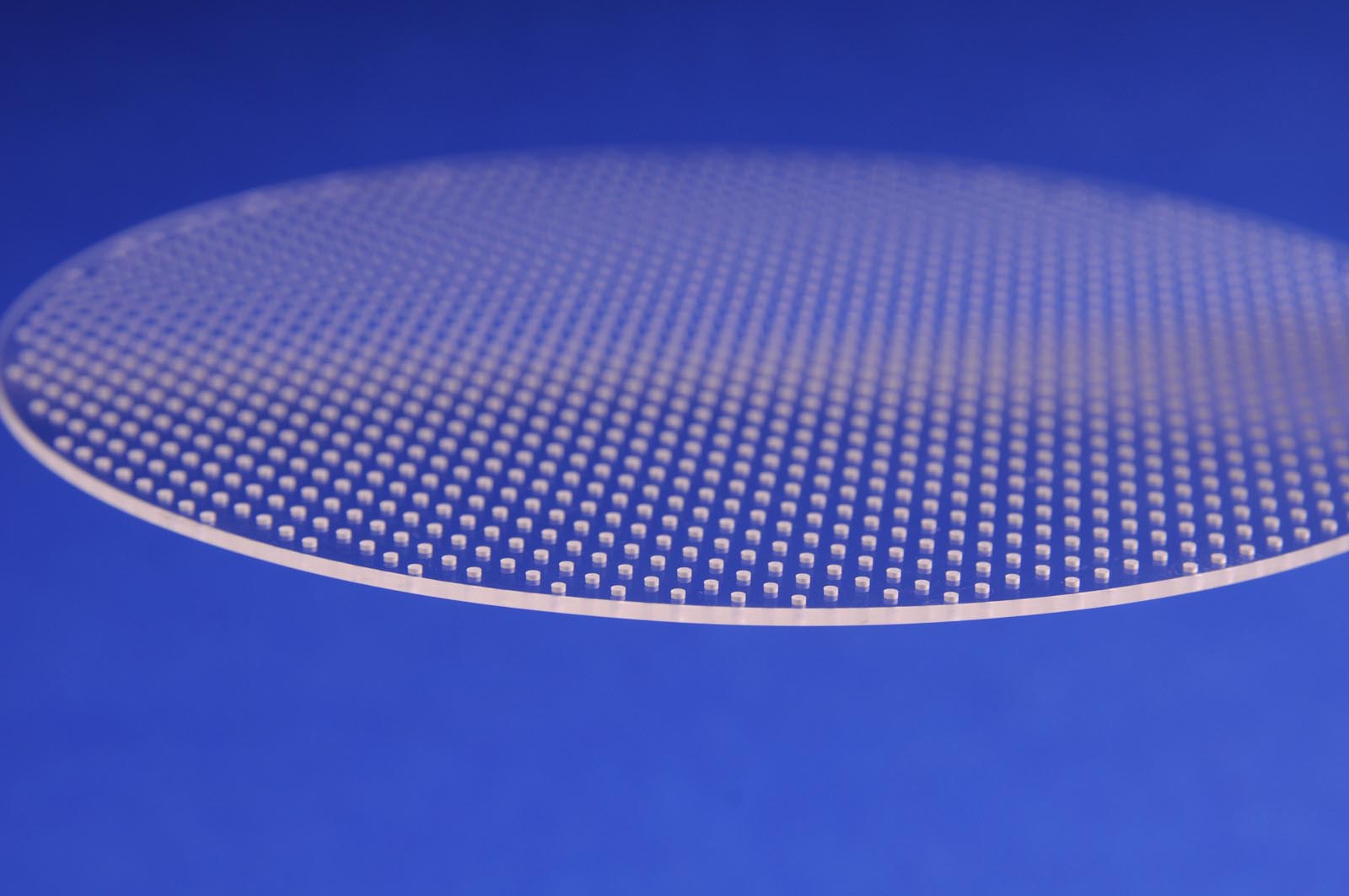

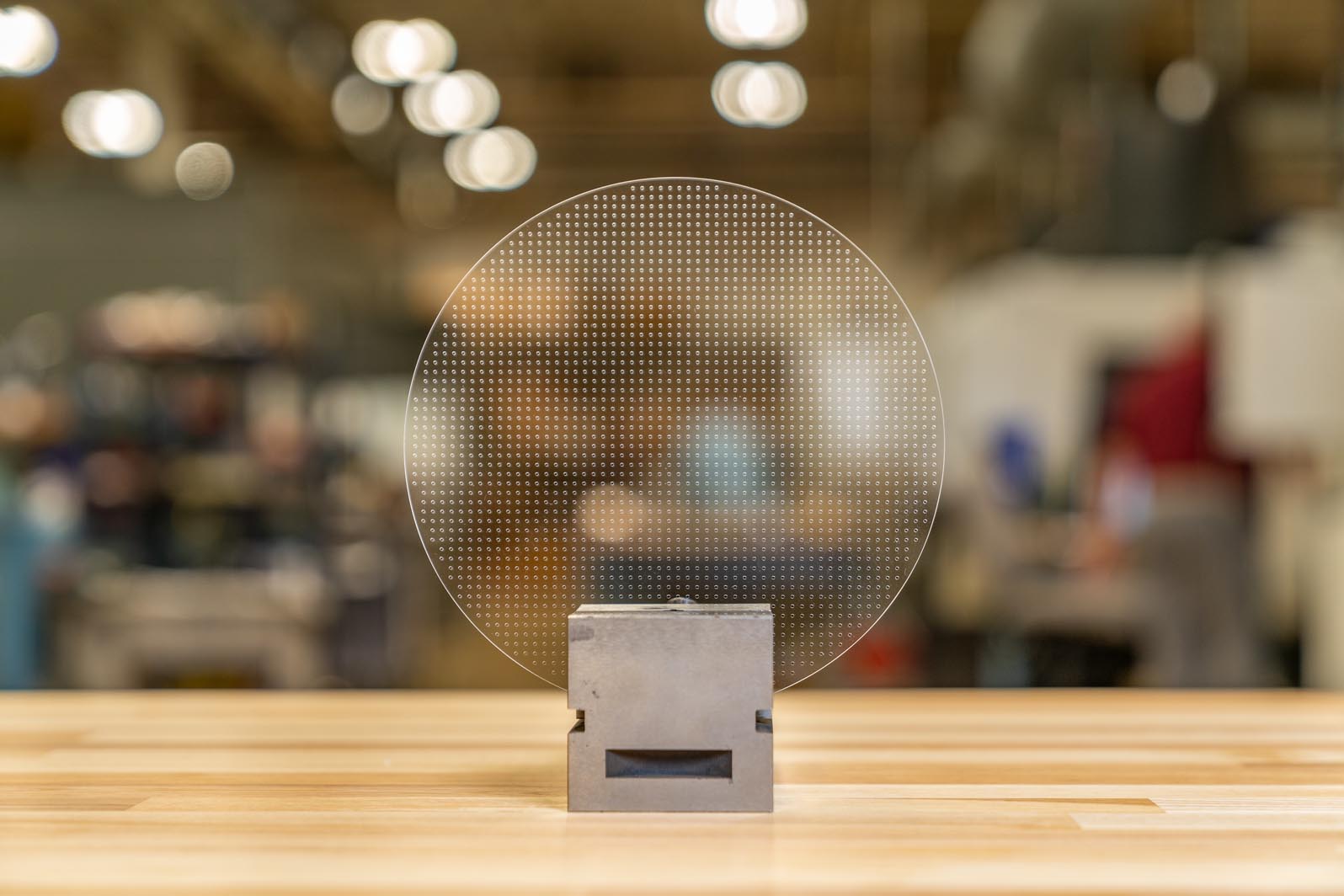

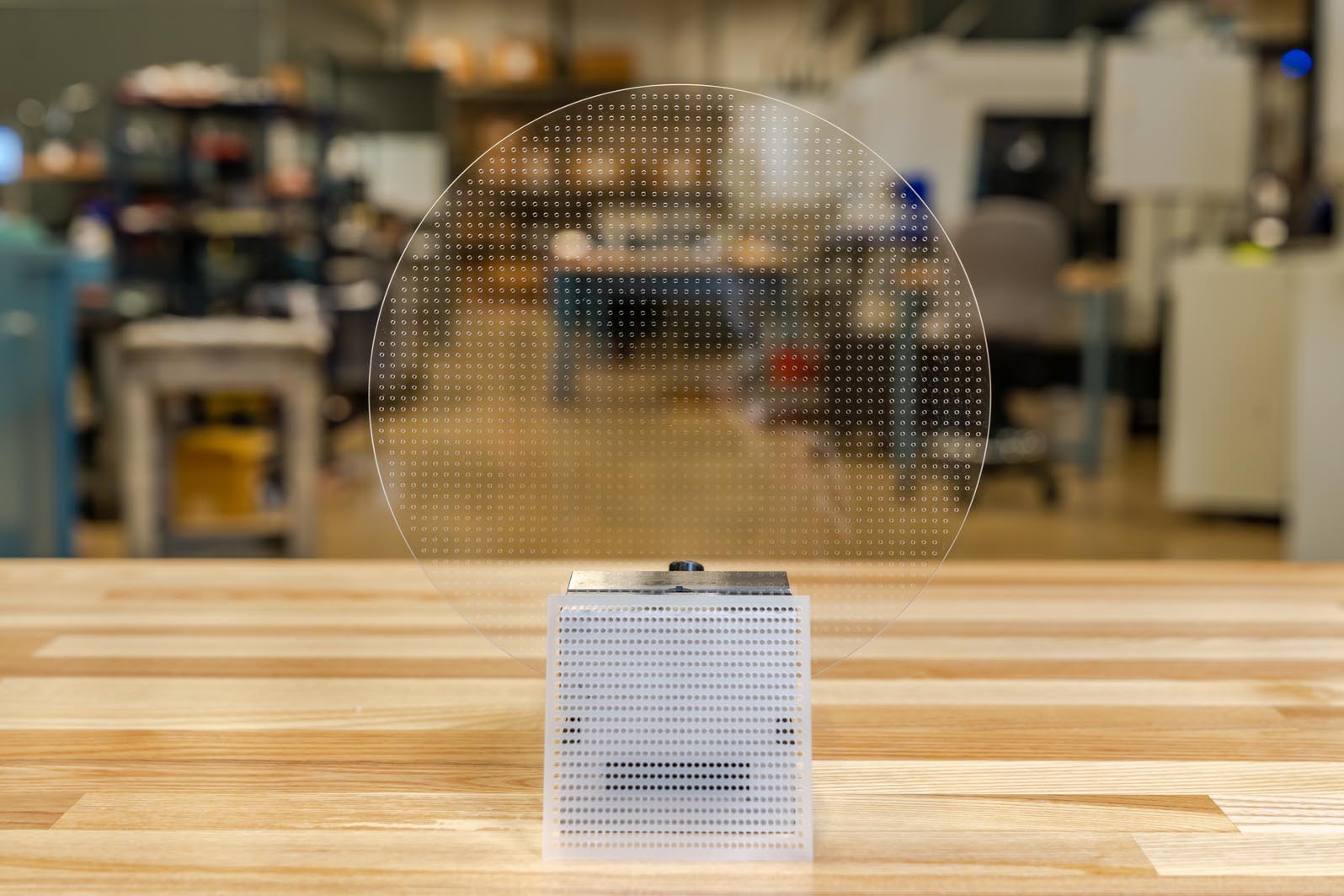

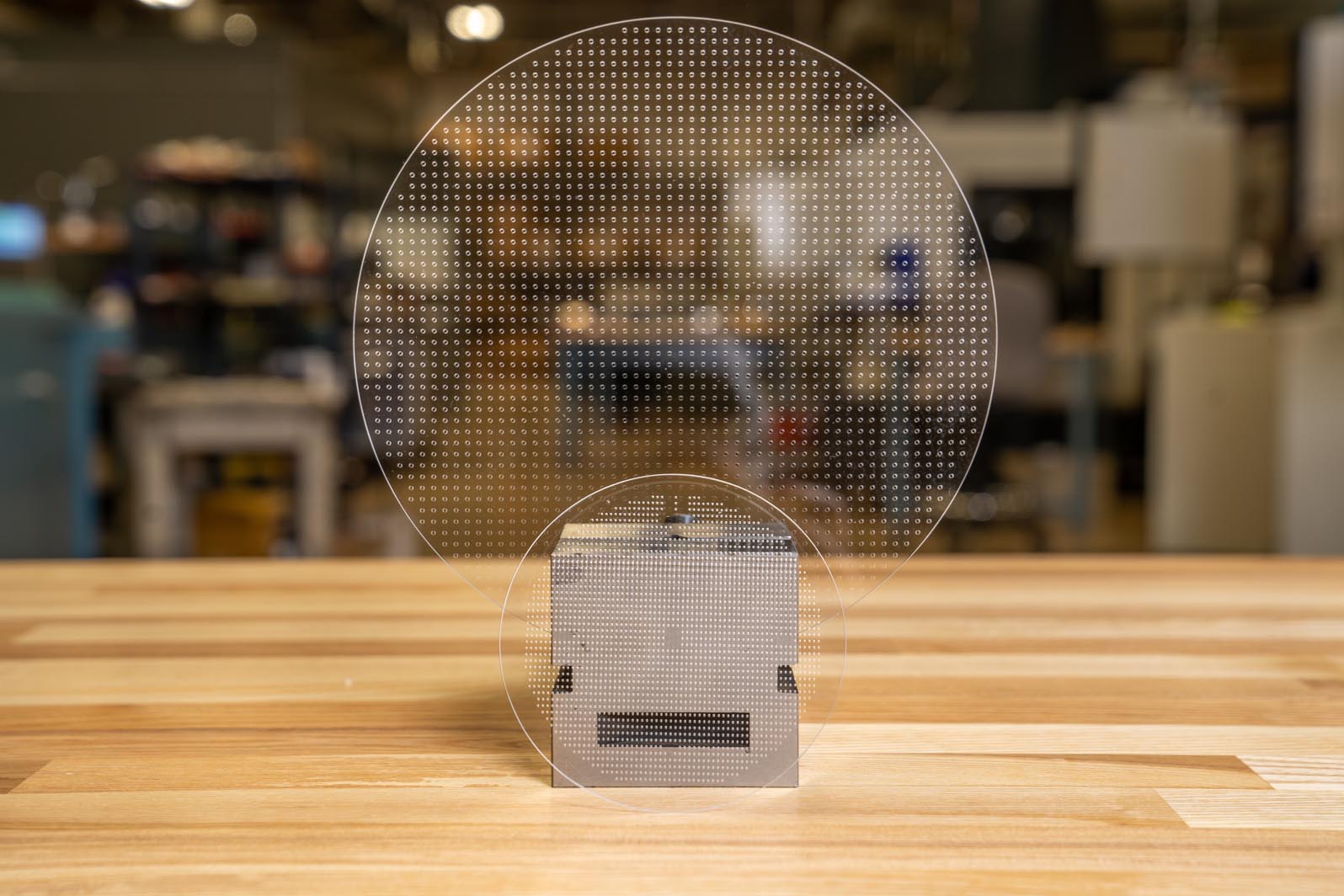

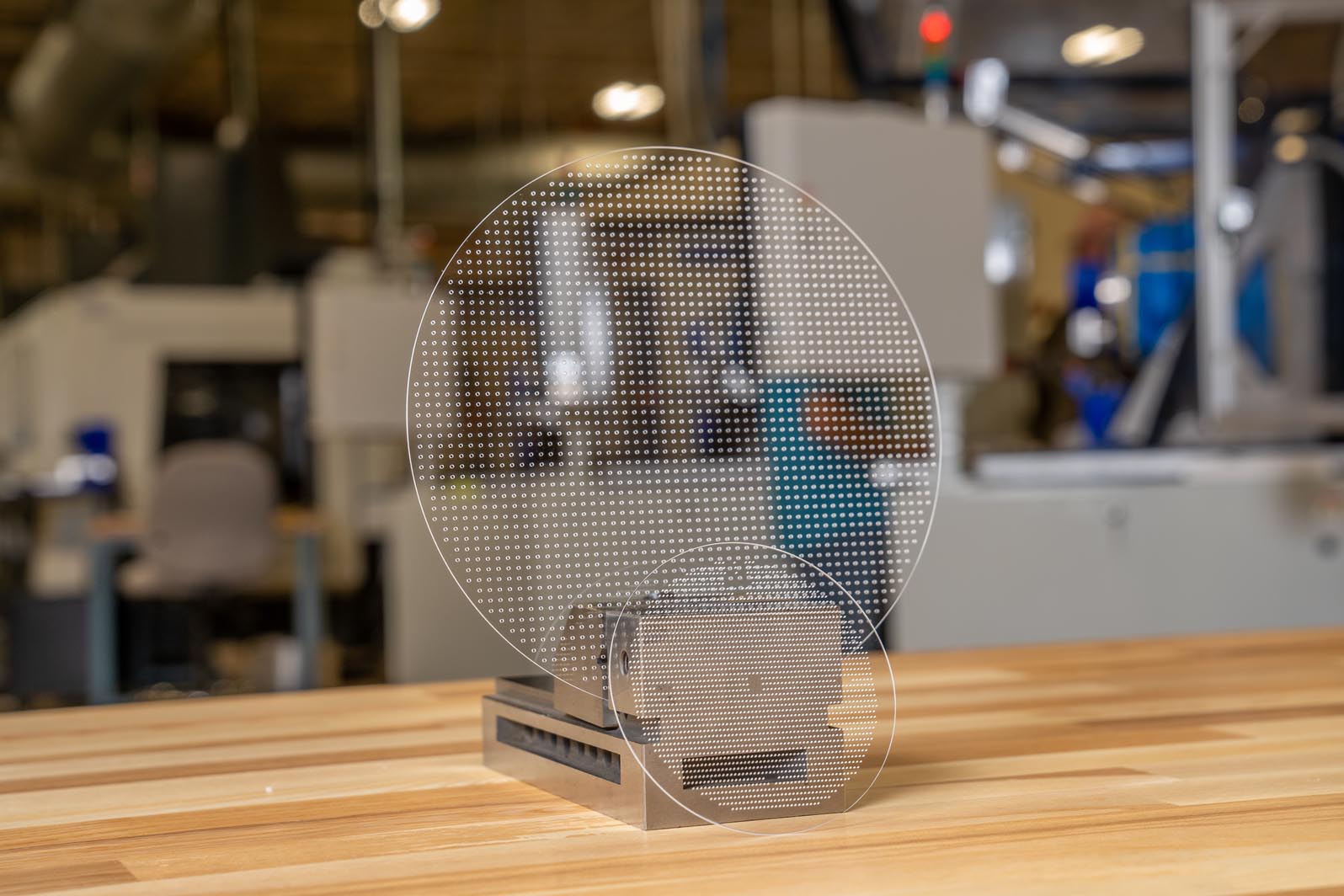

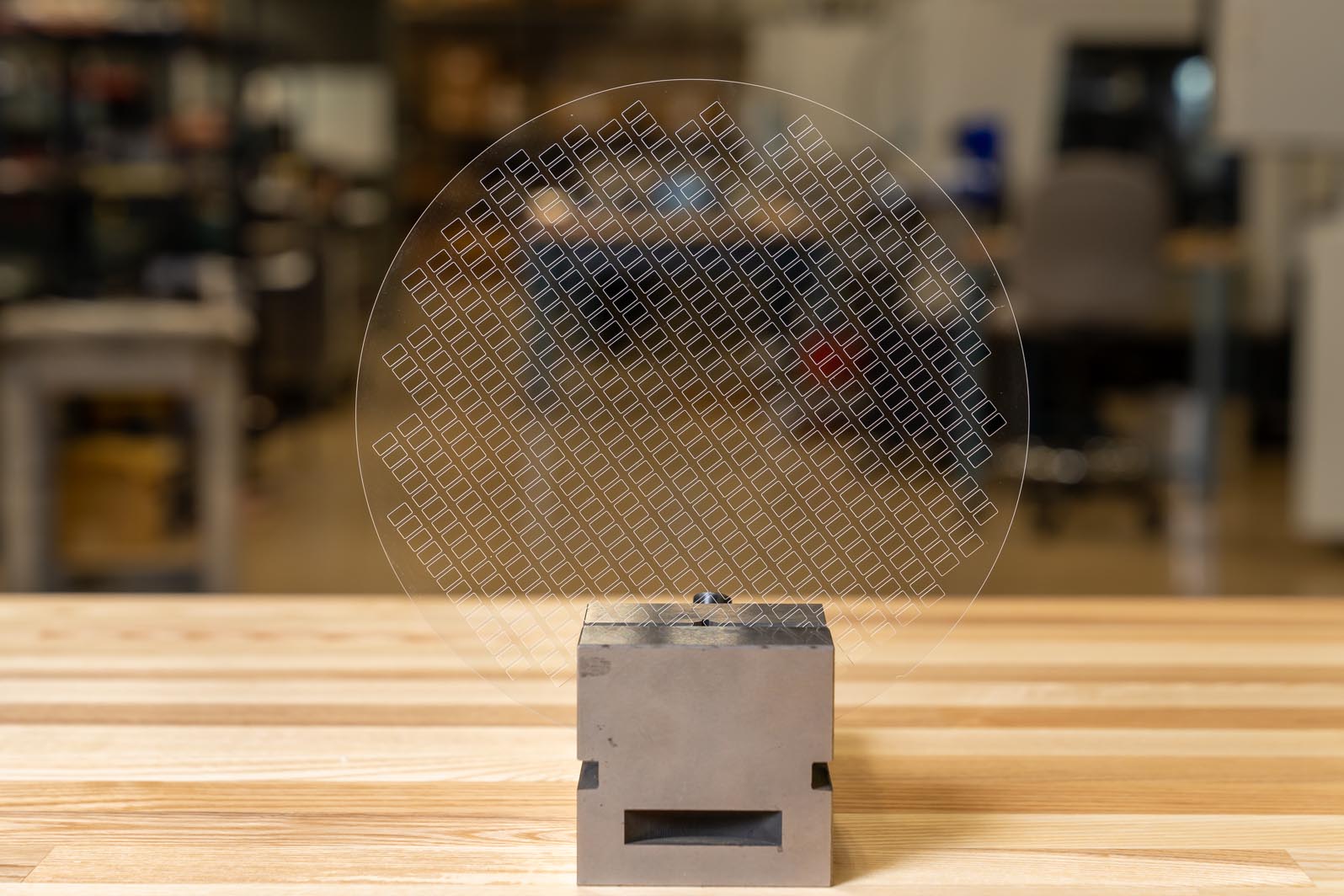

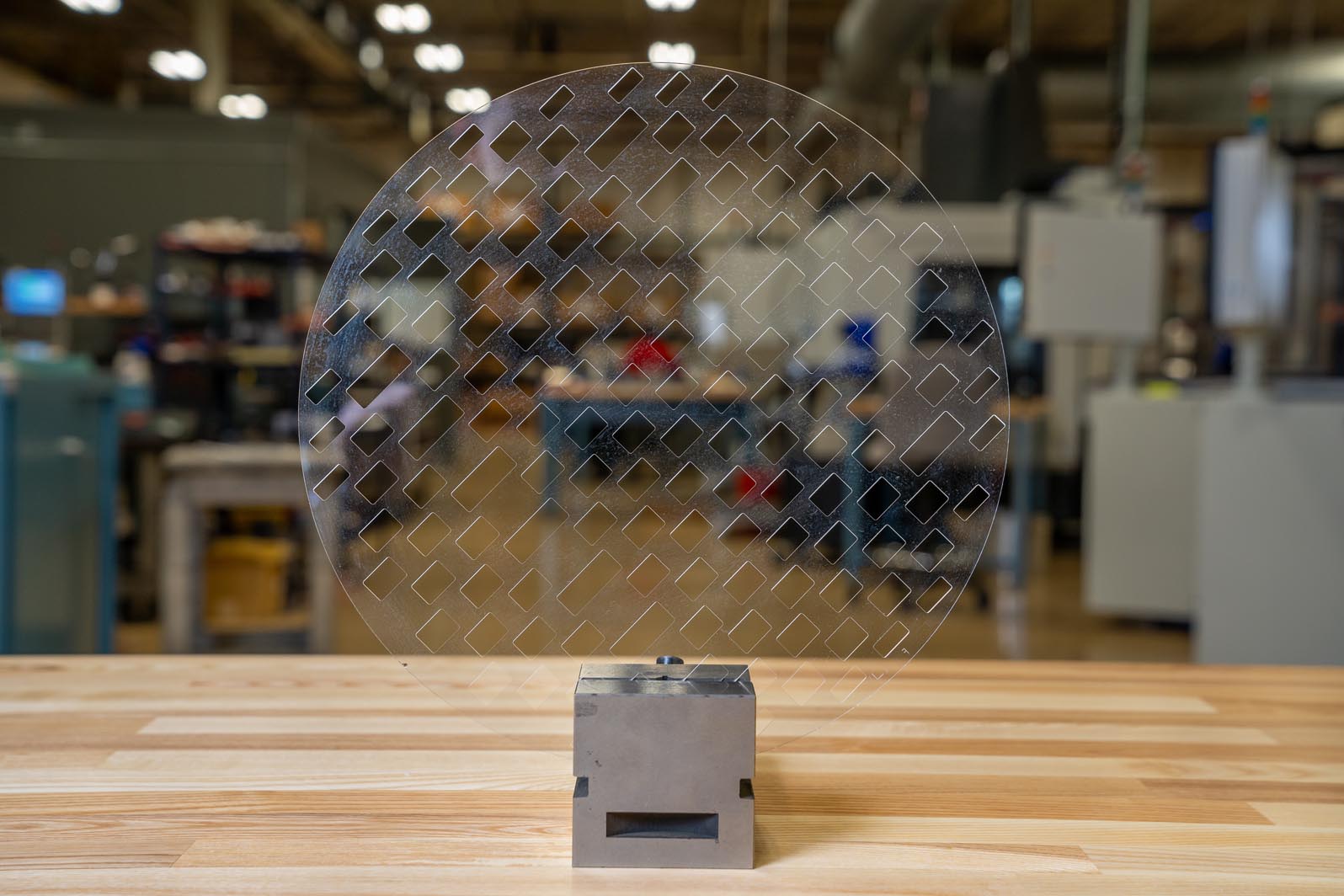

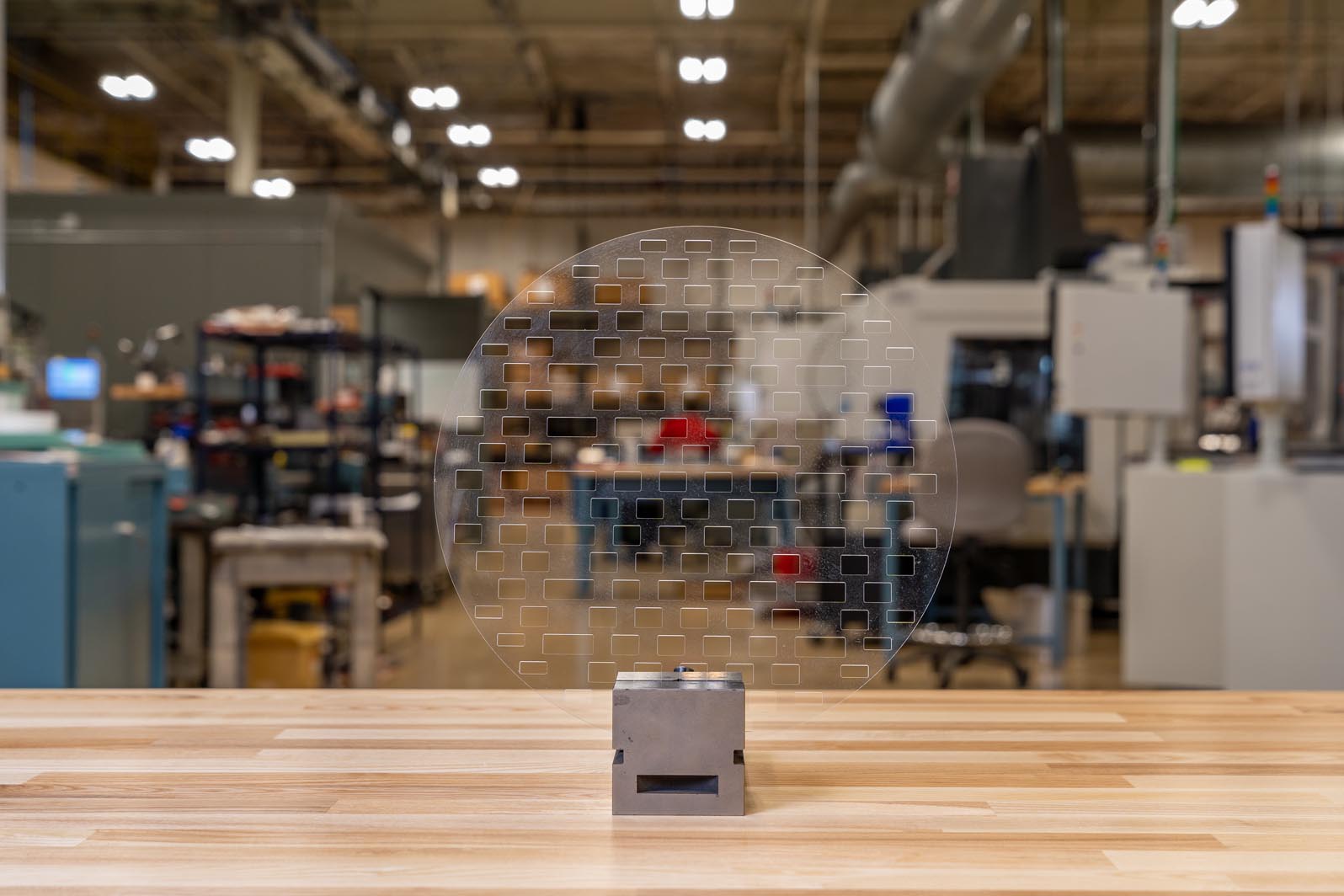

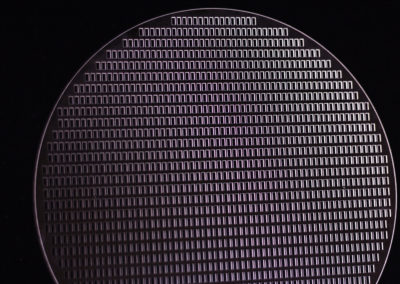

We use proprietary laser drilling technology to cut precise features in transparent materials so your team can execute its vision.

Materials We Machine ↓

MicroLucent® Machining can be used in transparent materials, including:

- Glass

- Sapphire

- Quartz

Features and Patterns Possible ↓

Bullen can machine a limitless number of different cuts and shapes, including:

- Round Holes

- Rectangular Holes

- Odd-shaped holes

- Slots

- Blind Cuts

- Cavities

- OD and ID Work

- Blind Cavities

Applications for MicroLucent® Machining ↓

Applications for MicroLucent Machining include:

- MEMS Glass Devices

- Quartz Semiconductor Gas Distribution Plates (GDP)

- Microfluidics Devices

- Through Glass Vias (TGV)

- Glass Interposers

Advantages of MicroLucent® Machining ↓

Bullen’s MicroLucent Machining process has many advantages over traditional machining.

- Micron level tolerancing

- Superior yields

- No damage to substrates

- No HAZ

- High throughput

GET IT ALL

MicroLucent® Machining offers high-precision quality at an affordable cost.

GLASS THICKNESS: UP TO 15MM

MINIMUM MICROHOLE DIAMETER: 40 µm

FEATURE ACCURACY: +- 10 µm

POSITIONAL ACCURACY: +- 15 µm

MIMIMUM PITCH 10 µm

TAPER ANGLE: NONE

CHIPPING: NONE

MICRO-CRACKS: NONE

A Simple Process to Solve Your Complex Engineering Need

1

Talk to Our Team

2

plan

3

Prototype & pilot

4

produce

News

At the heart of our mission is a simple but powerful idea: being a collaborative partner. To us, that means showing up with curiosity, technical expertise, and a willingness to dig into the unknown alongside our customers. One recent project with a customer in the additive manufacturing space—trying to break into the automotive industry with […]